Manufacturers in the United States account for almost 11% of the total output in the state, employing 8.58% of the workforce, according to the U.S. Bureau of Economic Analysis and the U.S. Census Bureau.

Over the years, manufacturing processes have significantly improved. However, there’s one key area that still poses a challenge for manufacturers: traceability. Without knowing where exactly a product is or came from, it’s challenging to handle emergencies such as recalls.

Read on to learn more about traceability in the manufacturing supply chain and how it can benefit you.

What Is Product Traceability?

Other than being a legal requirement in some sectors, traceability is increasingly becoming essential in manufacturing. It is the ability and process of tracking all the components and products within the manufacturing process. It starts with raw materials entering the factory and continues even when you ship final products.

A key element of the traceability process is product traceability. This involves tracking manufactured goods from production to where they will be shipped. With product traceability, you’ll also be able to track a product from where it is in the market, and trace back all the operational steps.

Why Is it important?

A common misconception about traceability is that it’s primarily for products subject to recalls. These are mostly safety products such as airbags and foodstuffs. However, that’s not the case. Even if you are not subject to strict compliance guidelines, traceability is essential in modern manufacturing.

During the process, key information about the raw material or product is recorded from end to end. These include:

- Assembly details

- Inspection results

- Time spent at each station

Such information gives you real-time visibility into operations. This is invaluable for many instances, such as when products at the end of the production line are defective. The reasons for this may include:

- A new operator handled the products

- Components from the defective products are from one supplier

- The products did not go through a particular check

- The products went through one machine

Traceability allows you to track each step the products went through. This makes it easier to pinpoint the problem and address it. So, whether it is employee training or faulty machinery, you’ll soon know.

Benefits of Traceability

The manufacturing process is often complicated and cumbersome. Traceability can help make it easier and more efficient.

1. Root Cause Analysis

Bottlenecks in manufacturing are common and somewhat unavoidable. The best thing you can do is to try and reduce them. And, when they do occur, you should address them swiftly. With both, identifying the underlying issue is key. Otherwise, formulating a solution will be problematic.

From the data traceability offered on raw materials and products, performing root cause analysis will be easier. This not only facilitates a swift resumption to normalcy but also minimizes the impact.

2. Competitive Advantage

Traceability is a multi-beneficial investment. It offers you invaluable data giving you more insight and visibility of the production and process. From this, you can identify and address issues before they become problematic.

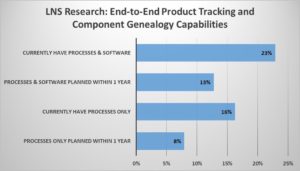

An LNS Research report suggests that only 23% of manufacturers have the necessary software and processes to achieve full traceability. Therefore, investing in full traceability will help you gain a competitive advantage.

Source: LSNResearch.com

3. Product Recalls

At some point, you may have to recall products from the market if they’re defective. This often means recalling many products as you are not sure which ones, in particular, are bad. However, with full traceability, you can pinpoint defective ones. As a result, you can reduce the recall from tens of thousands to a few products.

How to Achieve Full Traceability

There are a lot of things that come into play when implementing traceability. It involves thorough record-keeping, tracking, proactive monitoring, and performing trial recalls. This is why it’s important to have traceability software. It will make all these processes easier and more efficient.

About the author

Alina Akk is a marketing and communications professional with a proven track record of success growing SaaS businesses. A tech enthusiast and an avid reader, she loves to write about direct-to-consumer trends, e-commerce, and latest software products impacting the manufacturing industry.